What are the methods of SMT first part inspection(FAI) ? The following are some common first-part inspection analysis methods can be based on different production technology requirements, usually choose a different first-part inspection study method although the method used has different, but the final effect is the same.

SMT first inspection (FAI)

1. The first part is inspected with a meter, the resistance and capacitance values are inspected with a meter, and the BOM table is checked, but the operation is troublesome and easy to make mistakes.

2. LCR measurement, commonly known as the bridge, for some of our relatively simple circuit board circuit board components are few, there is no an integrated system circuit, only some passive components after assembly, LCR is used to directly measure the components on the circuit board compared to the BOM on the component rating, no abnormalities can start formal production.

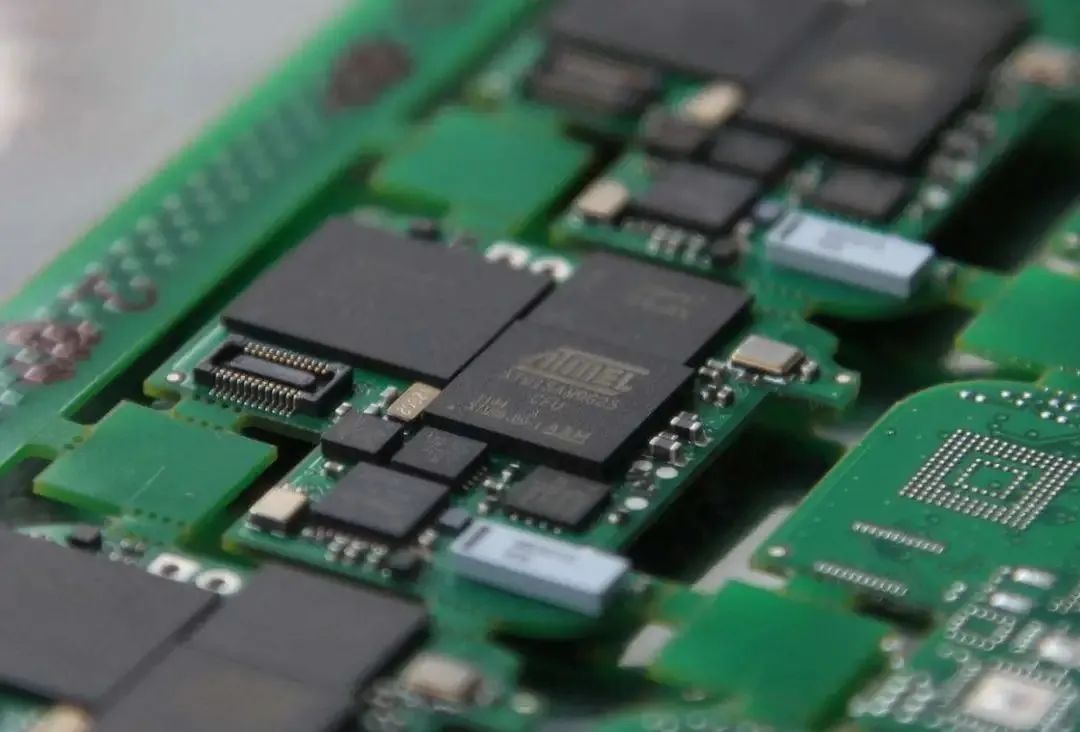

3. FAI first article test management system design usually consists of a set of LCR bridge integrated by FAI software. Production product BOM can be imported into the FAI system, enterprise employees can use their own bridge fixture to measure the first sample components system will check with the input BOM data, test process software through graphics or voice display test results, reducing the carelessness of personnel in the search process caused by test errors.

4. AOI testing in the SMT industry development is very common, applicable to all circuit board production is mainly can be determined by the appearance of electronic components features to determine the components of the welding technology problems, but also by checking the color of the components and IC on the screen printing to determine whether the circuit board has the wrong components.

5. X-ray for inspection, used to pass some need to install a hidden solder joints, such as BGA, CSP, QFN package system components and circuit boards, QFN production of the first block needs x-ray inspection, X-ray penetration is very strong, is a variety of inspection occasions to use the instrument x-ray image can show the thickness of the solder joint shape welding quality and solder density.

6. Flying probe test, this system test work method method is usually used to carry out some small batch production, its characteristics are easy to test, program variability, good generality, basic information can be based on testing all data types of circuit boards. But the test efficiency is low, each board test time will be very long.

7. ICT testing, this system test work method method is usually used in mass production models, and the production volume is usually relatively large, the test technology is very efficient, but the manufacturing production costs are relatively high each model of circuit board need to pass a special fixture, each fixture is not a long life, so the test environment to carry out the cost is relatively high.

8. FCT functional test, this test method is usually used for some complex circuit boards, after the board needs to be tested, you must use some special fixtures to simulate the official use of the board scenario, the board will be placed in the simulation to see if it can be used when the power is on.

Blue Eye Technology-SMT first piece tester

In today’s SMT electronics factories, multiple machine types, small batches, and frequent line changes make the task of first part inspection more and more demanding. The traditional SMT first part inspection method not only wastes manpower and is inefficient, but also lacks control over the entire first part inspection process, making it difficult to guarantee quality. In response to this problem, SMT first part inspection instrument, through continuous upgrading and optimization, now has the following six features: ▪ Automatic measurement judgment

▪ Automatic measurement judgment

▪ Improve the speed of detection

▪ Reduce labor costs

▪ Strictly standardize the process

▪ With traceability function

Improved product quality

With such significant advantages of the product, you do not see it?

SFG FAI machine

Post time: Mar-13-2023