Products

Micro focus X-ray inspection equipment X6800

Advantage

The X-ray source adopts the world's top Japanese Hamamatsu closed X-ray tube, which has a long life and is maintenance-free.

X-ray reception adopts a new generation of IRay 5-inch high-definition digital flat-panel detector, eliminating image intensifiers.

The flat panel detector instead of the stage can be tilted 60° without sacrificing magnification.Automatic navigation window, where you want to see where to click.

Load 10KG super large 530*530mm stage.

5 motion axis linkage system with adjustable speed.

The detection program can be edited to realize mass automatic detection, and automatically judge NG or OK.

The operation is simple and fast, quickly find the target defect, and two hours of training to get started.

Parameter

| X-ray source | Brand | Japan Hamamatsu | |

| Type | Closed、Micro-focus spot | ||

| Tube voltage | 130kV | ||

| Tube current | 300μA | ||

| Spot size | 5μm | ||

| Function | Preheating automatic | ||

| Flat panel detector | Brand | IRay | |

| Effective area | 130mm*130mm | ||

| Pixel size | 85μm | ||

| Resolution | 1536*1536 | ||

| frame rate | 20 frame/s | ||

| Tilt angle | 60° | ||

| Carbon fiber stage | Plateform size | 530mm*530mm | |

| Max pcb | 500mm*500mm | ||

| Max load | 10kg | ||

| Machine | Magnification | Geometric magnification 200X | System magnification1500X |

| Max test speed | 3 s/point | ||

| Dimension | L 1360mm,W 1365mm,H 1630mm | ||

| Net weight | 1350kg | ||

| Power | AC110-220V 50/60HZ | ||

| Max power | 1500W | ||

| Computer | I3-7100 CPU, 4G RAM, 240GB SSD | ||

| Display | 24 Inch HDMI display | ||

| Safety | Radiation leakage | None, international standard: less than 1 microsievert per hour. | |

| Lead glassobservation window | Transparent lead glass to isolate the radiation to observe the measured object. | ||

| Safety interlockingof front and rear doors | Once the door is opened, the X-ray tube is poweredoff immediately, and the X-ray cannot be turned on when the door is opened. | ||

| Electromagnetic safety door switch | When the X-ray is turned on, it locks itself and cannot open the door. | ||

| emergency button | Located next to the operating position, press to immediately power off. | ||

| X-ray tube protection | After turning off the X-ray, you can leave the software for other operations. | ||

Software

|

functional module |

Operation | Keyboard and mouse |

| X-ray tube control | The X-ray can be turned on or off by clicking the button with the mouse, and the real-time tube voltage and tube current values are displayed next to it. The user can click the up and down buttons, or drag the

slide bar, or manually enter the adjustment. |

|

| Status Bar | By whether the red and green flashes alternately, it prompts the interlock status and preheat status

State and X-ray switch state. |

|

| Image effect adjustment | The brightness, contrast and gain of the image can be adjusted freely to achieve satisfaction

Effect. |

|

| Product list | The user can store the current or recall the previously stored Z-axis position, brightness, contrast, gain and other parameters. The same product can be directly

recalled next time to improve the inspection efficiency. |

|

| Navigation window | After the camera takes a photo of the platform, click

on any position of the photo, and the platform will move until the position is displayed on the screen. |

|

| Motion axis state | Display real-time coordinates. | |

| Test results | Display each measurement result in sequence (bubble ratio, distance, surface

Product and other measurement items set by the customer). |

|

| speed control | The moving speed of each axis can be adjusted to slow speed, normal speed and fast speed. | |

|

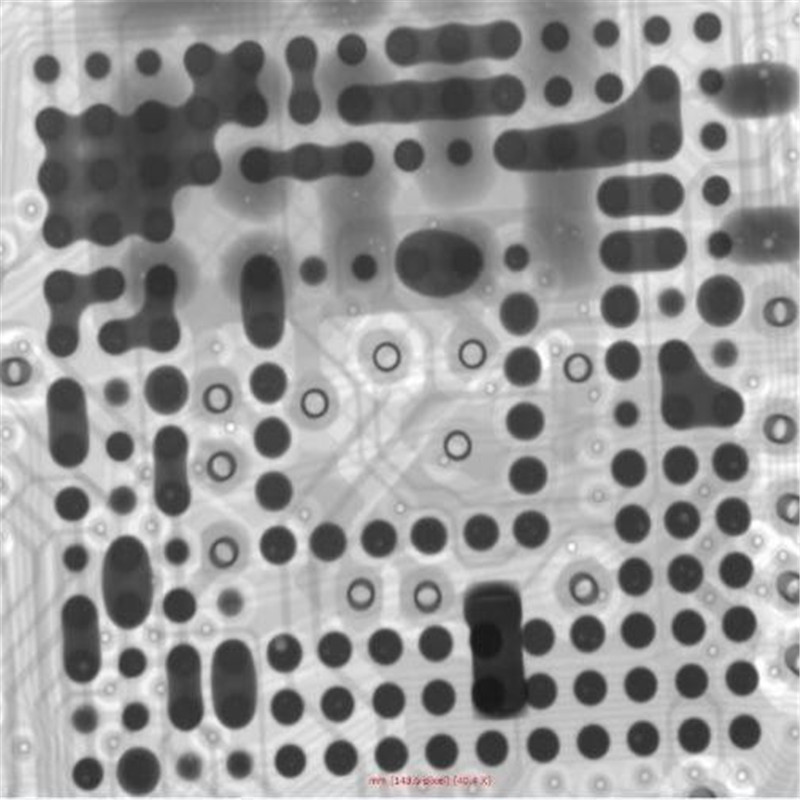

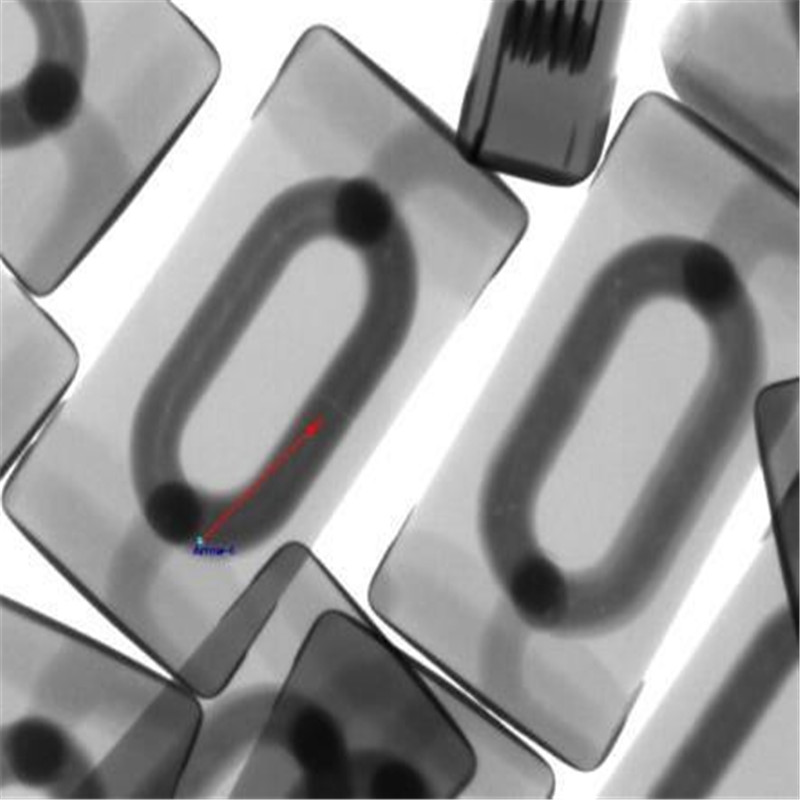

Bubble rate measurement |

Automatic calculation |

Click two points to determine a rectangle. The software automatically finds and measures the solder ball edges, pads and internal bubbles in the rectangle, and can get the solder ball bubble rate, solder bal area, circumference, maximum bubble ratio, length, width and other data , And use red and green to

indicate NG or OK. |

| Adjustment parameters | The user can adjust the grayscale threshold, pixel,

contrast, size filter and other parameters to get the accurate result of the automatic calculation. |

|

| Add bubbles manually | Users can draw polygons or free graphics, which are calculated into the bubble rate as bubbles. |

| Bubble rate measurement | Store parameters | The user can store the grayscale threshold, pixel, contrast, size filter and other parameters of the current measurement bubble, and the same product can be called directly next time to improve the

detection efficiency. |

| Other measurement functions | distance | Click the two points A and B to set the reference line as needed, and then click point C to measure the

vertical distance from point C to the reference line. |

| Distance ratio | It is mostly used to measure the through-hole tin rate of the circuit board. A point D is set more than the measured distance. The vertical distance from point D to the reference line is divided by the vertical distance of point C to obtain the percentage ratio of

the vertical distance of D to C. |

|

| angle | Click the two points A and B to set the baseline as needed, and then click point C to measure the angle

between the BA and BC rays. |

|

| Round shape | It is mostly used to measure round components such as solder balls. Click three points to confirm a circle,

and measure the circumference, area and radius. |

|

| Square | It is mostly used to measure square components, click two points to confirm a square, and measure the length, width and area. | |

| automatic detection | Set location manually | The user can set any position on the platform as a detection point, and the software will automatically take and save the picture. |

| Array | For the inspection points with regular arrangement, the user only needs to set two inspection points and the number of rows and columns, and the software will automatically take each inspection point and save

the picture. |

|

| Automatic Identification | For the detection points with obvious characteristics, the software can automatically identify the specific location, perform the measurement, and save the

picture. |

X-RAY applications

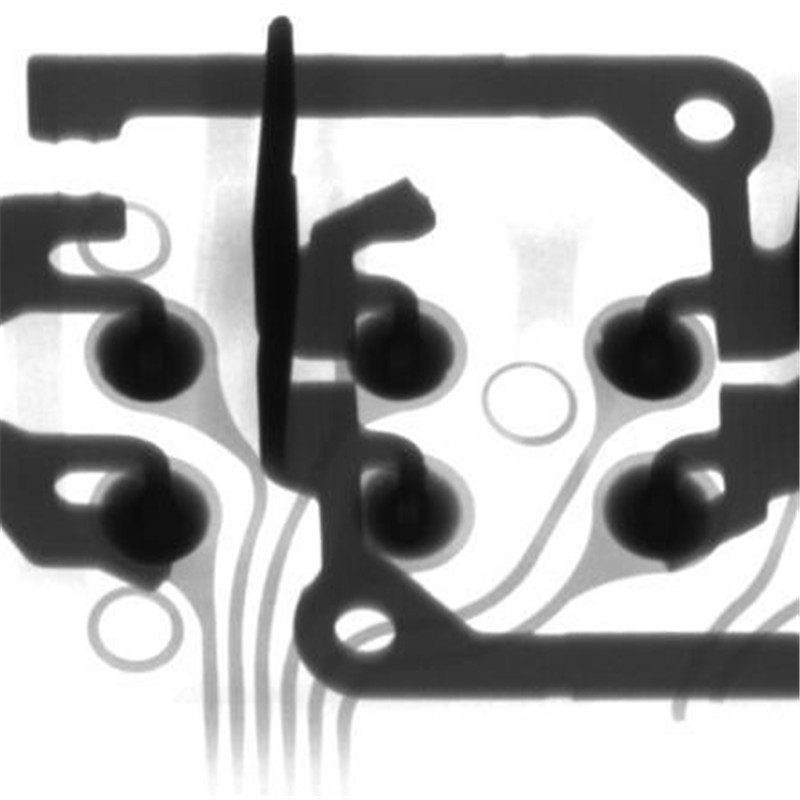

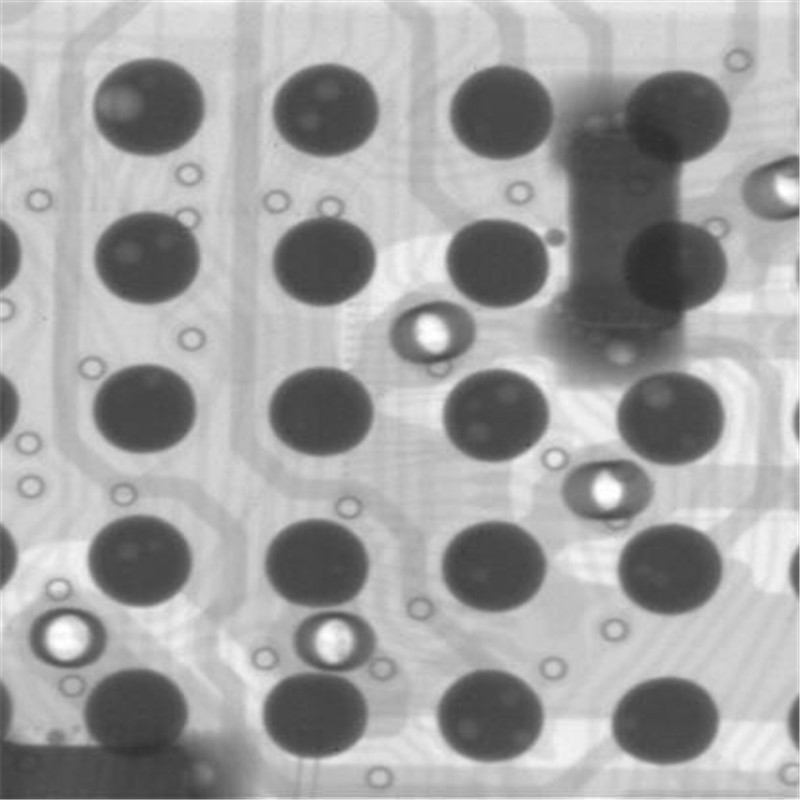

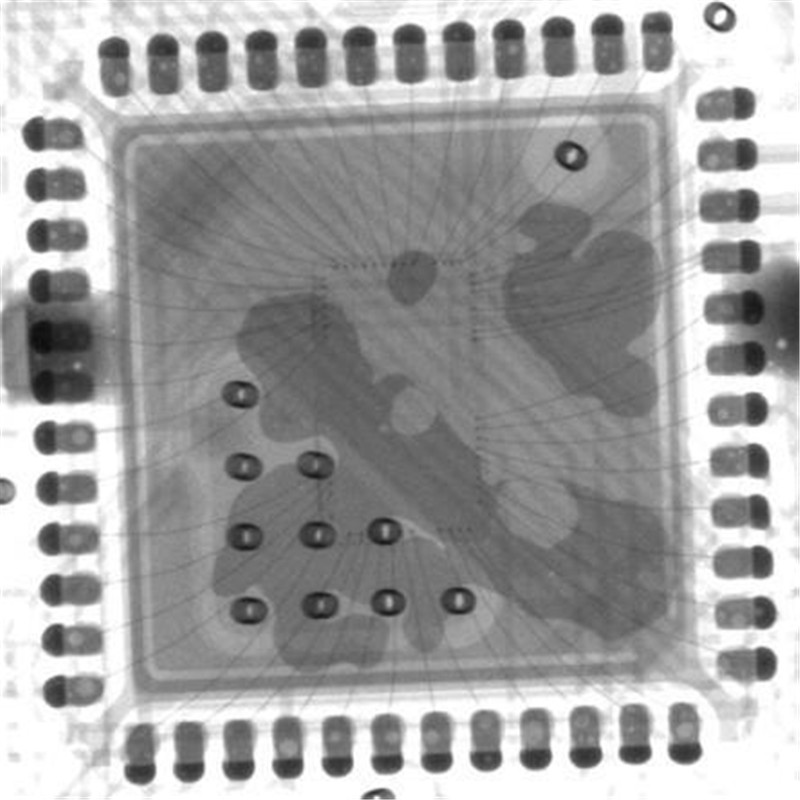

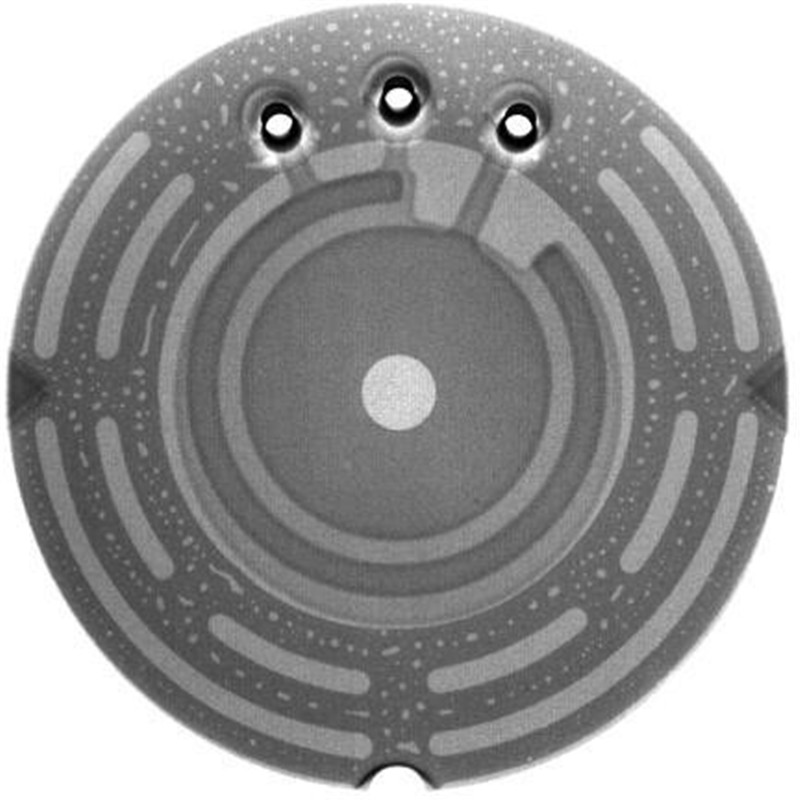

BGA solder connection

BGA bubble

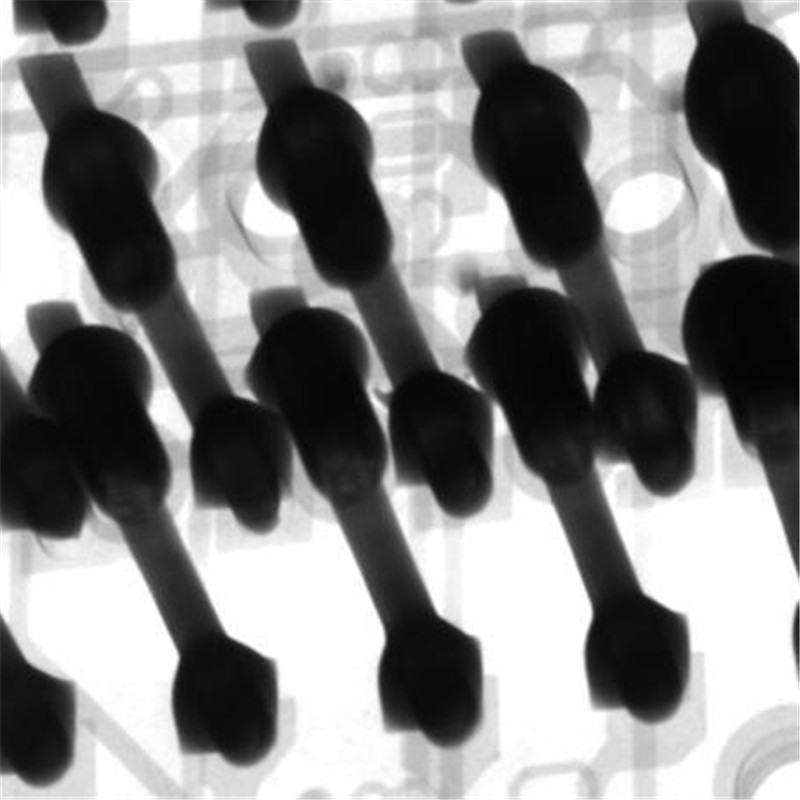

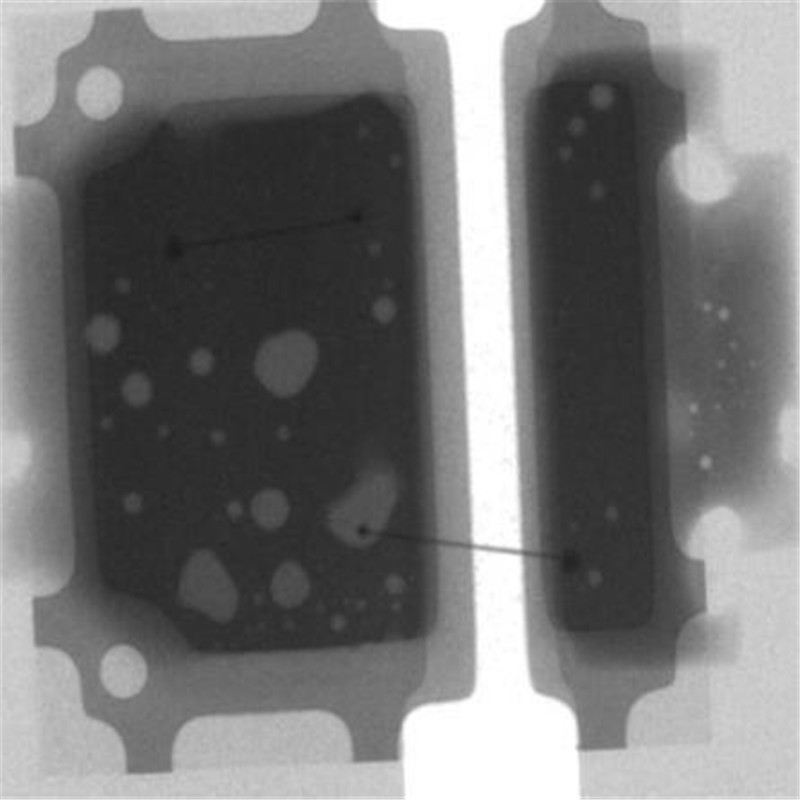

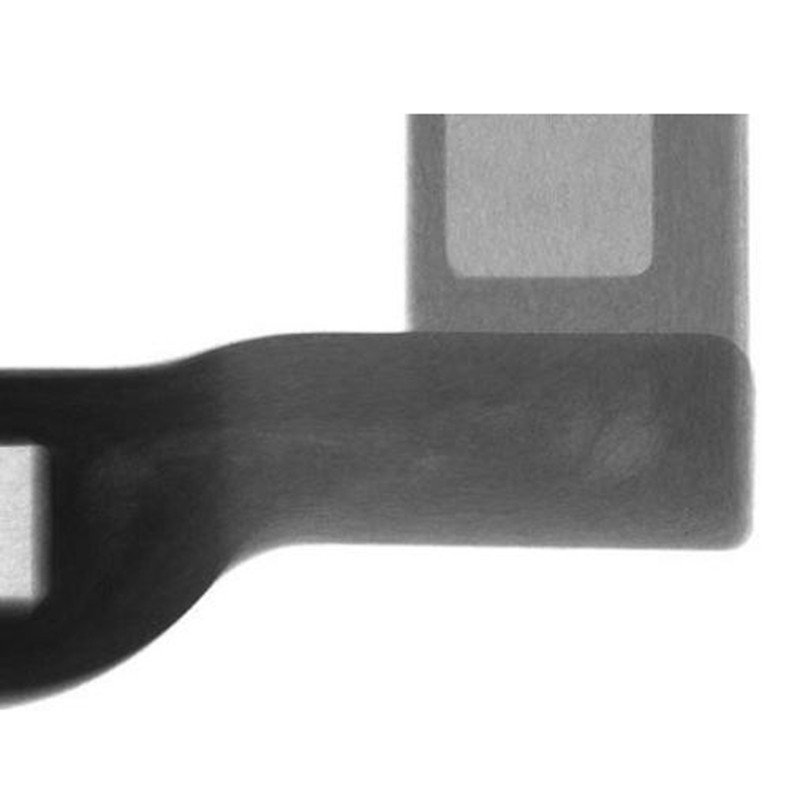

PCB Through-hole through tin

IC Bubbles and gold thread

LED Welding bubbles

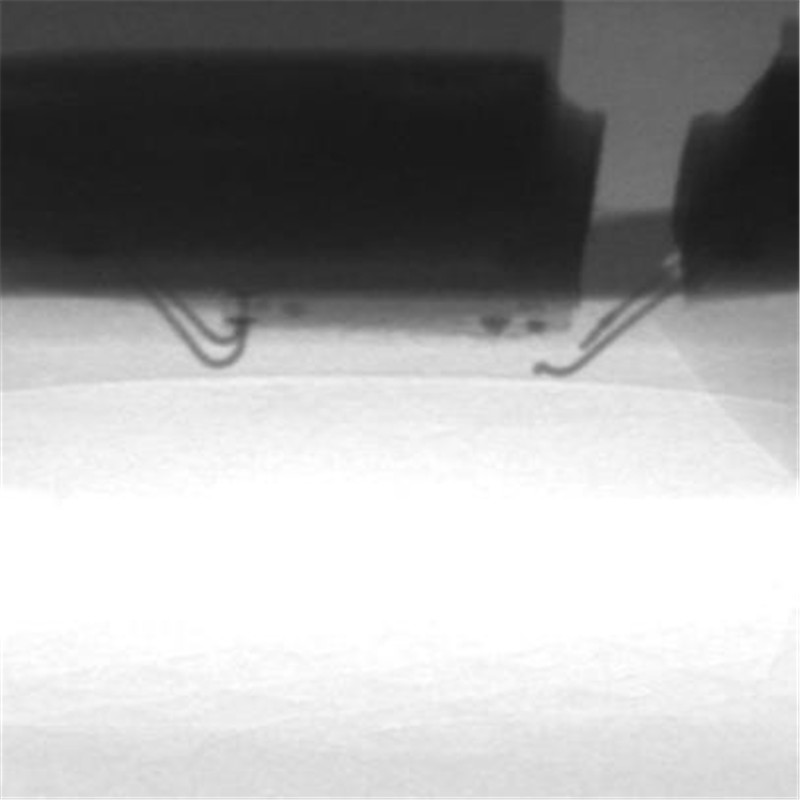

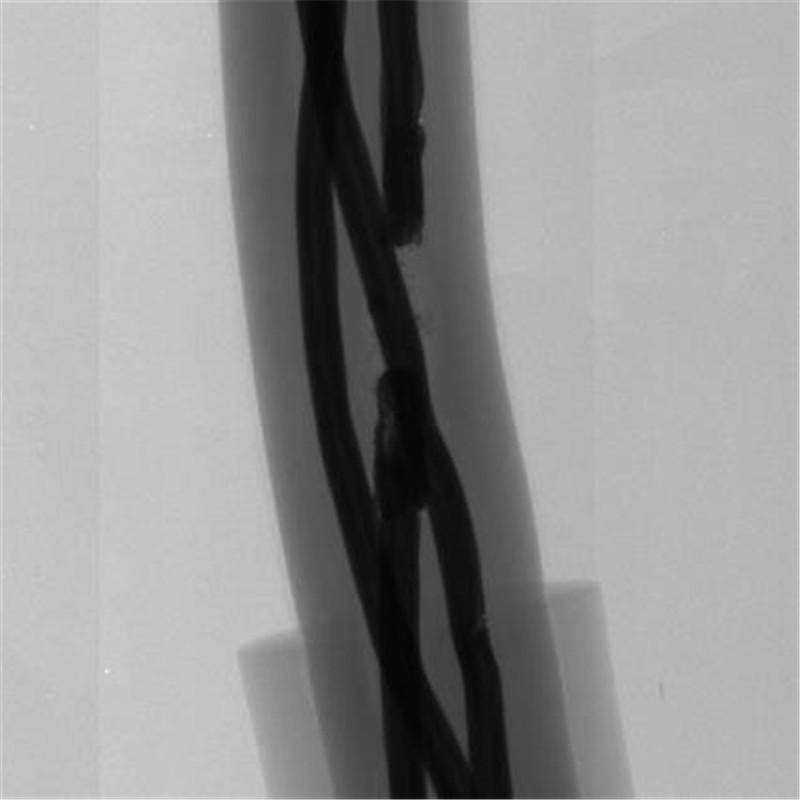

Led gold wire broken

Capacitance

Inductor

Sensor

Semiconductor discharge tube TSS

Glass fiber plastic

Cable

Diode

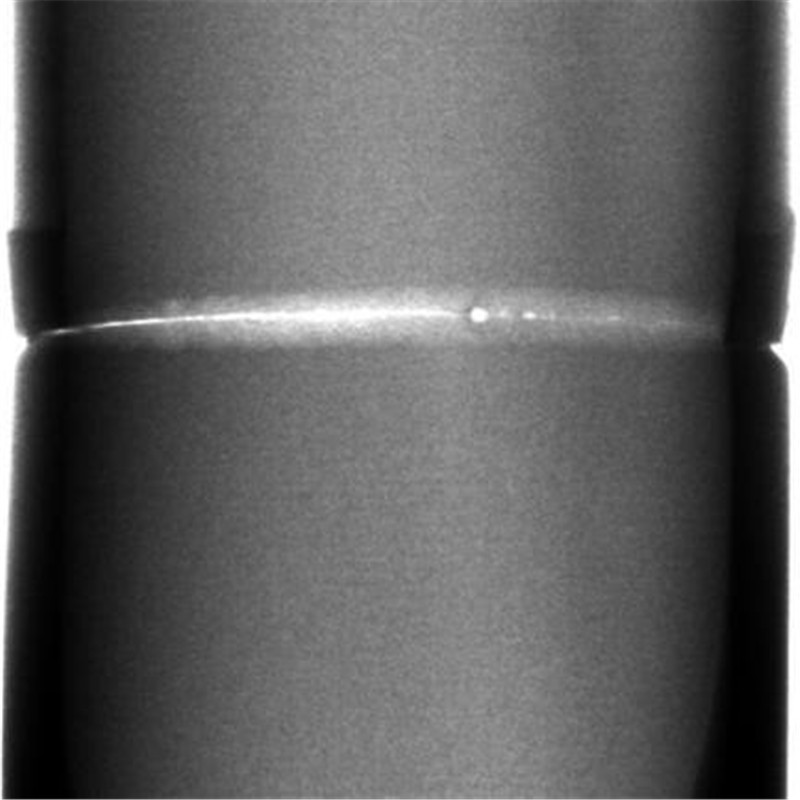

Steel pipe welding gap

Car chisp