Products

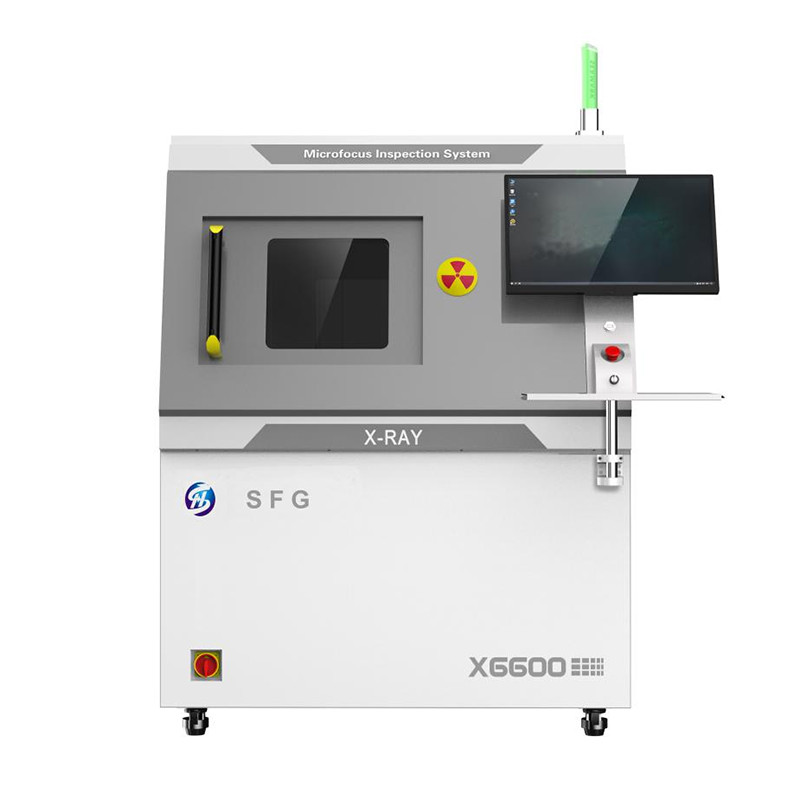

X-Ray Solution X6600 Microfocus X-Ray Inspection System Manufacturer

Advantage

| 1: Semiconductor | 2: Automotive electronics | 3: PCB’A | 4: LED |

| 5: BGA/QFN inspection | 6: Aluminum die casting | 7: Mould | 8: Electrical and mechanical components |

| 9: Biological agriculture seed | 10: Aviation component | 11: Wheel hub | 12: Wire/USB/Plug |

Functions and Features

|

Function |

Advantages |

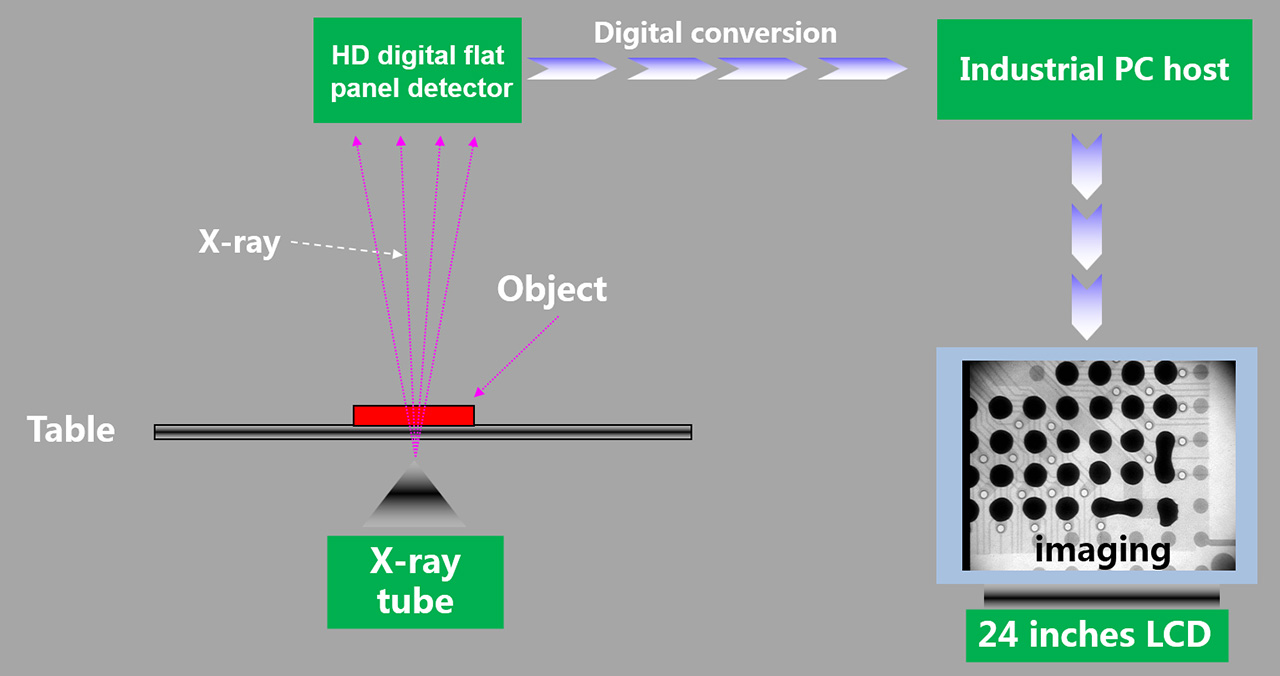

| X-ray tube and detector can move along Z direction, Speed of table moving along X-Y direction can be adjusted. | Larger effective detection range, improving the magnification and the detection efficiency of the product. |

| High-definition digital flat panel detector.

Max Inclined Angle is 65°, samples can be observed with a unique perspective |

Easy to identify the side defects of the product and achieve no dead angle detection. |

| Long life X-ray tube, maintenance free for life | Adopt the world's top Japanese Hamamatsu X-ray source |

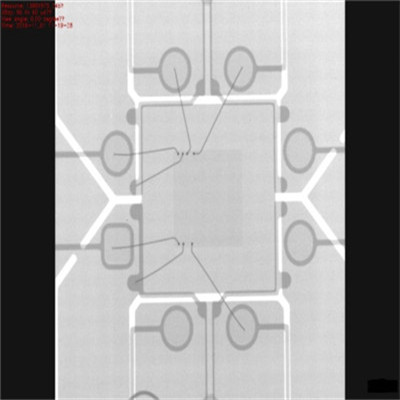

| Fault less than 2.5μm can be detected. High detection repeat accuracy. | Easy to distinguish the gold wire bending and break of the semiconductor package. |

| Powerful CNC Measuring Function, can test automatically, testing program can be edited. | Suitable for large-scale inspection and improve detection efficiency. |

| Large inspection space, can put various large-sized samples. The table can carry 10KG items. | Large table for large industrial control boards, ultra-long LED strips, and electronic products for various fields |

| Large navigation view, table will move to where you click the mouse. | Very easy to operate, quickly find item defects and improve detection efficiency |

Hardware Technical Parameters

|

X-Ray Solution X-6600A Hardware technical parameters |

||||

|

H A R D W A R E |

X-RAY tube

|

Tube type |

Sealed microfocus X-ray tube |

|

| Tube voltage |

40-90kV |

|||

| Tube current |

10-200uA |

|||

| Focal spot size |

5-15μm |

|||

| Cooling method |

Convection cooling |

|||

|

Detector |

Detector type |

HD digital flat panel detector (FPD) |

||

| Imaging area |

130mm*130mm |

|||

| Pixel matrix |

1536*1536 pixels |

|||

| Inclined Angle |

0-60° |

|||

|

Inspection speed and accuracy |

Repeated test accuracy |

3μm |

||

| Software inspection speed |

3.0s/point (Excluding loading and unloading time) |

|||

|

Table |

Standard size |

540mm*440mm |

||

| Effective inspection area |

500mm×410mm |

|||

| Load capacity |

≤5Kg |

|||

|

CNC programming |

Test parameters for different products can be stored in categories and called at any time. You can set the detection route or sequence of one or more products, and the program automatically completes the detection and stores the photos. | |||

|

Operating platform |

Mouse, keyboard, 2 operating modes | |||

|

Shell |

Inner lead plate | 5 mm thick lead plate (isolate radiation) | ||

| Dimensions | 1360mm(L) * 1240mm(W) * 1700mm(H) | |||

| Weight | 1250Kg | |||

|

Other parameters |

Computer | 24 inches Widescreen LCD/I3 CPU/2G Memory/200G hard disk | ||

| Power supply | AC220V 10A | |||

| Temperature and humidity | 22±3℃ 50%RH±10%RH | |||

| Total power | 1700W | |||

|

Safety |

Radiation safety standard | Adopt steel-lead-steel protection structure. Any position 20mm from the shell, radiation≤1μSV/H, in line with international standards | ||

| Safety interlock function | Two high-sensitivity limit switches are set in the door opening position for equipment maintenance. Once the door is opened, the X-ray tube will automatically power off immediately. | |||

| Electromagnetic switch protection | The observation window has an electromagnetic switch, and the observation window cannot be opened when the X-ray tube is in working state. | |||

| Observation window | With an observation window, the sample can be observed directly from the window while the machine is running. | |||

| Emergency stop | The emergency stop is set in the prominent position of the operation console and the equipment body, can be pressed to quickly cut off the power supply system. | |||

| X-ray tube automatic protection | Five minutes after the machine has no operation, the X-ray tube will automatically power off and enter the protection state. | |||

| Automatic machine protection | Once any door or window of the machine is turned on, the machine immediately enters the shutdown protection state, and any operation cannot be performed. | |||

Software technical parameters

| X-Ray Solution X-6600A Software technical parameters

Full-featured X-ray image analysis software, including image contrast enhancement and filtering functions, measurement functions, and CNC programming |

|||

| S

O F T W A R E |

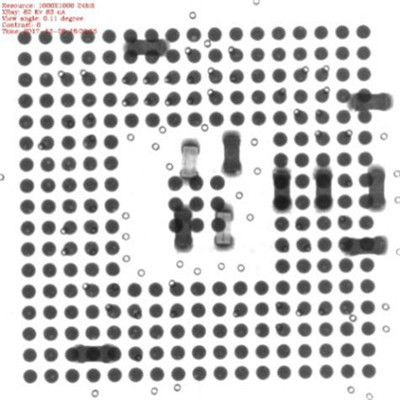

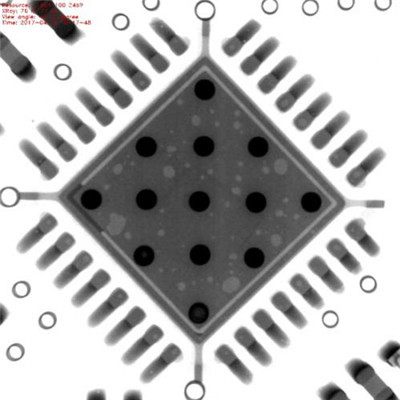

Bad welding judgment | BGA short | Preset NG images, software contrasts and recognizes automatically |

| BGA cold solder | Preset NG images, software contrasts and recognizes automatically | ||

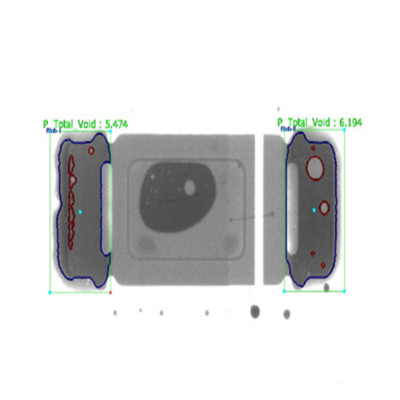

| BGA voids | Preset NG images, software contrasts and recognizes automatically | ||

| BGA false solder | Preset NG images, software contrasts and recognizes automatically | ||

| CNC function | Motion mode programming (CNC) | Test parameters of different products, can be classified and stored, call at any time | |

| Can set the inspection route or sequence of one or more products | |||

| Navigation window | The picture of the table is displayed on the screen in real time, Click any position of the picture to control the movement. | ||

| Voids measurement | Voids rate measurement | Optional manual/automatic measurement, single/multi-ball measurement mode. The bubble area standard can be preset for automatic measurement. | |

| Report generation | The judgment result can be directly marked on the picture, or directly generate a CSV file or a report document according to the analysis results. | ||

| Measurement function | Area measurement | Preset area size standard, NG product prompt function. | |

| Size measurement | Distance, gold line curvature, slope, angle, etc. | ||

| Motion control | Automatic positioning | Power on table auto zero function, system reset | |

| Batch test | Import pre-production program to realize fast automatic positioning function, convenient for large-scale inspection and product series management | ||

| Field of view switching | The interface can be quickly switched between 2 inches and 4 inches to realize the two detection requirements of large field of view browsing and partial detail observation, saving detection time and improving detection efficiency. | ||

| Control mode | CNC Automatic control, manual control keyboard, mouse, 3 modes are optional. | ||

| Auxiliary positioning | Laser positioning | Red dot laser positioning, double auxiliary, easy to navigate | |

| Navigation magnifier | It can enlarge the product detection points in the navigation window, which is easy to accurately locate and improve the detection efficiency. | ||

Table Control

1. Speed of table can be adjusted by the spacebar: low, normal and high speed.

2. X, Y, Z three-axis motion and inclined angle are controlled by keyboard.

3. Large navigator view, clear navigation image, table will move to where you click the mouse.

CNC Programming

Simply click the mouse and you can write programs.

Object table moves along X, Y direction for positioning; X-ray tube and detector move along Z direction for positioning.

Voltage and current set by software.

Image settings: brightness, contrast, auto gain and exposure

Users can change the pause time for program conversion.

Anti-collision system can maximize the tilt and observation of the workpieces.

Automatic analysis on diameter, proportion of cavity, area and roundness of BGA.

X-RAY applications

X-RAY applications

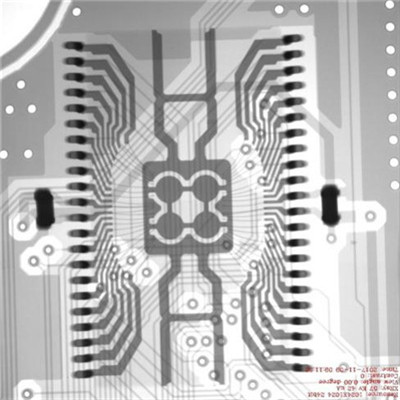

PCB BGA

iPhone camera

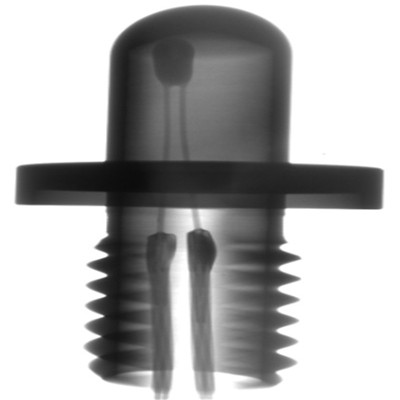

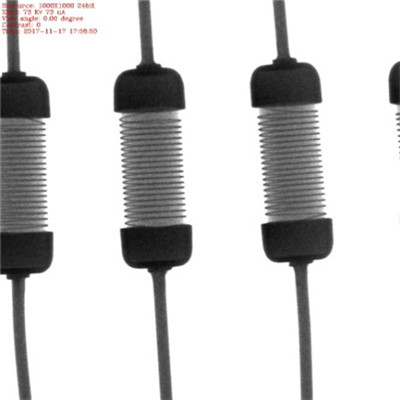

Diode

IC gold wire

Connector

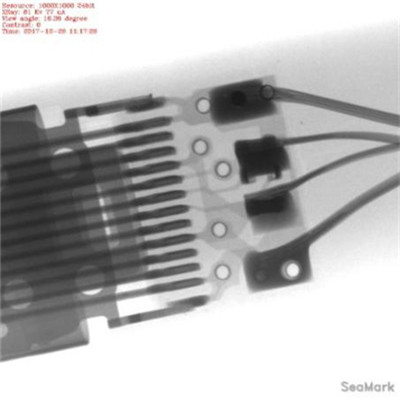

LED bonding wire

IC voids

IC voids

LED light

Thermal sensor

Diode capacitance

Soldering iron

iPhone mainboard

Chip gold wire

LED light voids

High power semiconductor IGBT module

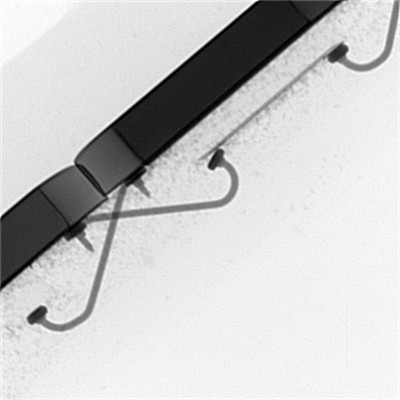

Luxury clothing fastener voids