Products

Selective wave soldering (S-455 )

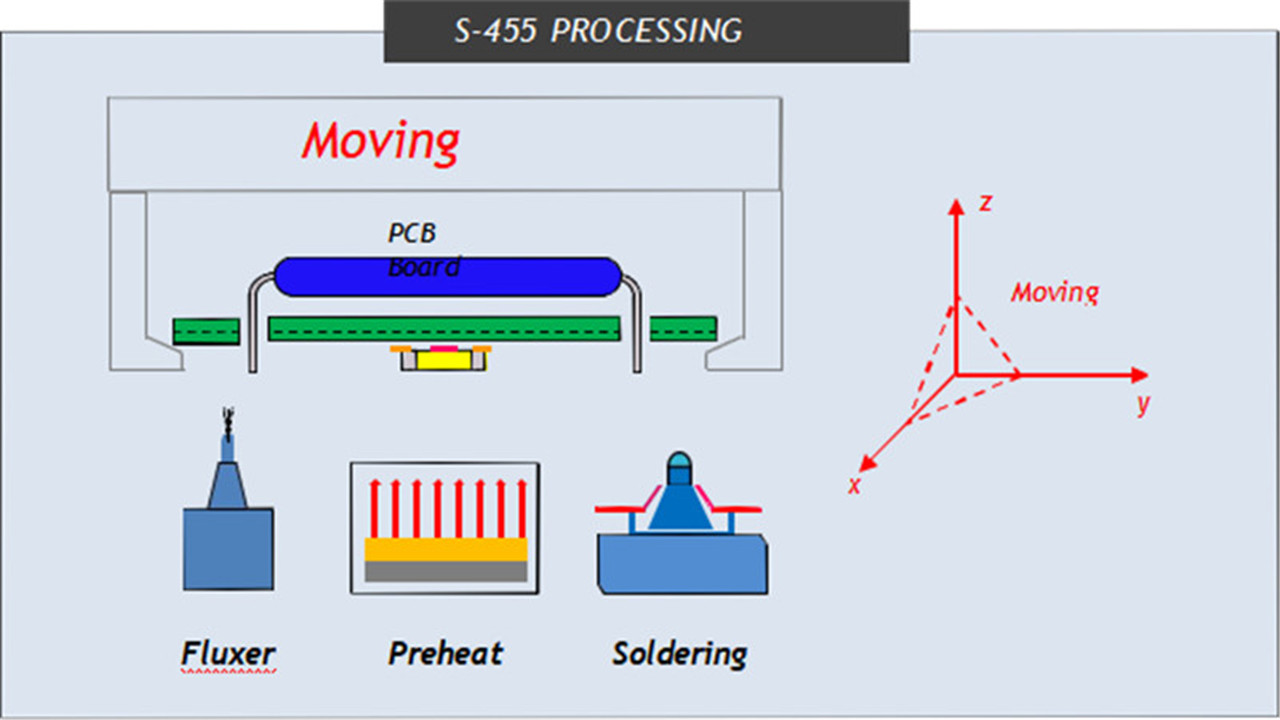

System process

Pcb loading manuall

PCB move to preheating zone’s top for

Move above fluxer nozzle withsettingpath

PCB move above soldering nozzle with

Unloading manually

Advantageous

● All in one machine, in same XYZ motion table combine selective fluxing and soldering, compact & full function.

● PCB board movement, fluxer nozzle and solder pot fixed. High quality soldering.

● Can used beside production line, flexible for production line forming. Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

Standard machine include

| Serial | Item | Item | Quantity |

| 1 | Controlling system | PC & monitor | 1set |

| Live on monitor camera | |||

| motion control | |||

| 2 | PCB Motion table | xyz motion table | 1set |

| axis equipped with ball screw & linear guild rail | |||

| 3 axis equipped with servo motor & driver | |||

| 3 | Fluxing system | Imported fluxing jetting valve | 1set |

| flux tank | |||

| flux pneumatic system | |||

| 4 | preheating system | IR heater at bottom | 1set |

| 5 | Soldering pot | 15kg capacity solder pot, impeller, tunnel, servor motor | 1set |

| solder temperature over heat alarm system | |||

| solder temperature controlling system | |||

| N2 inline heating system | |||

| (Internal diamter: 4mm x 3pcs, 5mm,6mm) Standard equipped solder nozzle | |||

| 6 | Conveyor system | PCB side clampingsystem | 1set |

| 7 | Machine chassis | machine frame/cover &painting | 1set |

Machine explanation

Part1: Software

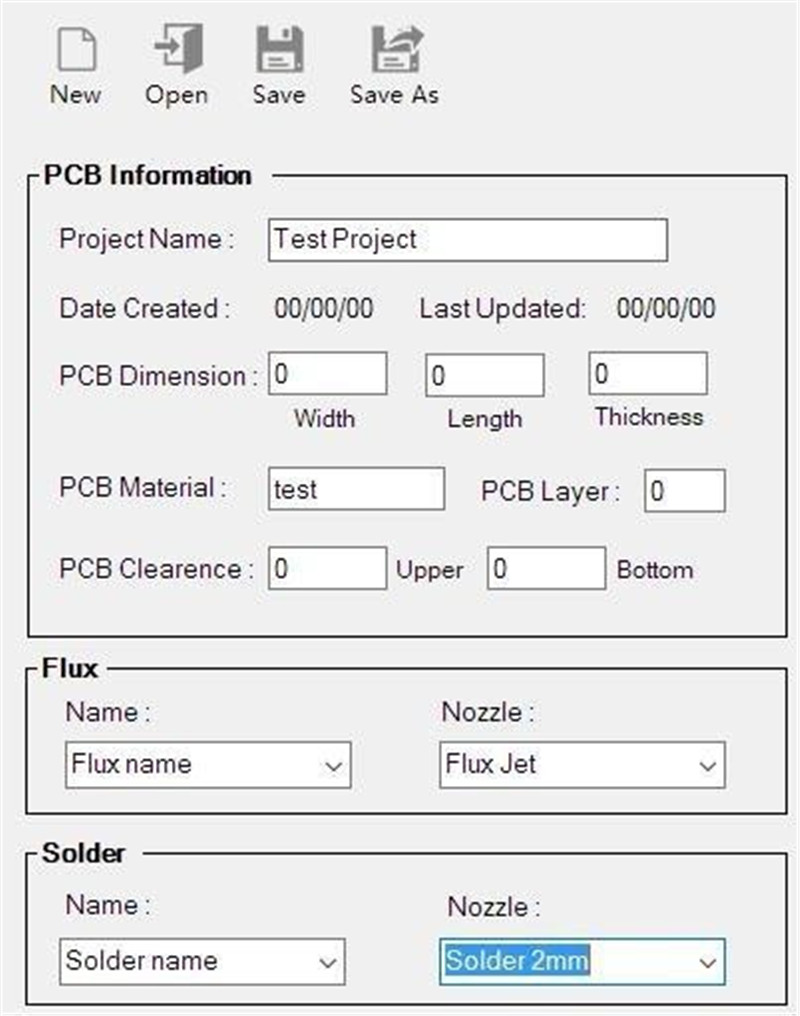

All software system developed by base on Windows7 system, with good trace-ability.

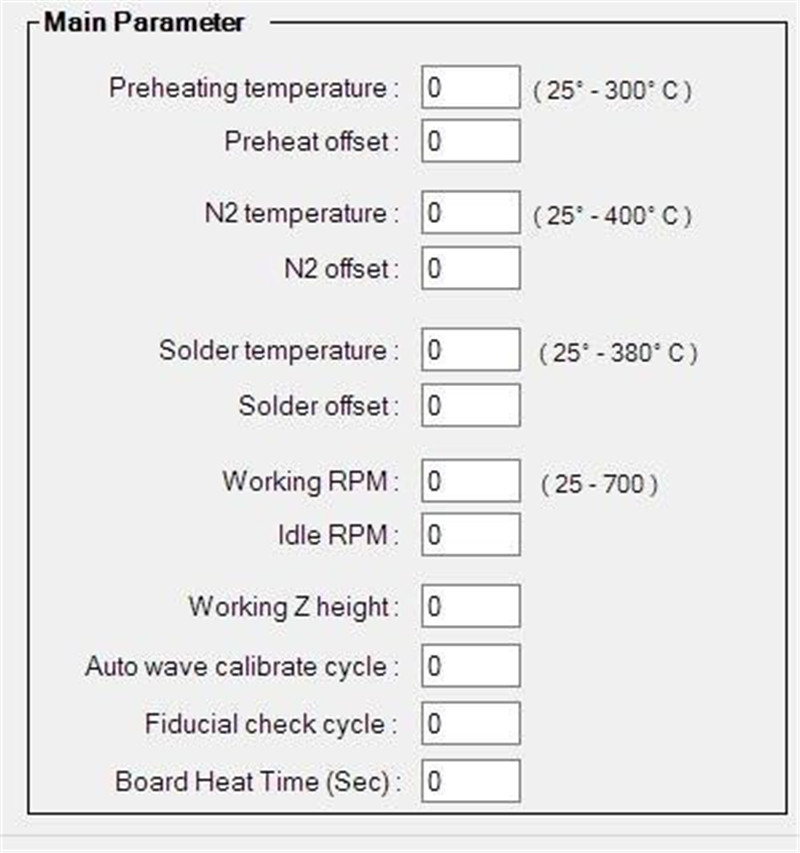

Use scanned picture as background for path programming, moving speed, dwell time, empty move speed, Z height , wave height etc all programmed for different solder site.

Show solder process with live on camera.

Critical parameters are totally under monitoring by PC software, like temperature, speed, pressure etc.

Can upgraded to be with auto wave height calibration function, to check & calibrate wave’s height after every certain pcb, so to keep a very good stability of wave.

Can upgraded to be with Mark positioning function, to check PCB’s mark point after every certain pcb, so to be reduce the pcb’s position offset.

About PCB’s menu in soldering machine, all information will be stocked in one file. It will include PCB dimension and picture, used flux type, solder type, solder nozzle type, solder temperature, N2 temperature, motion path and each site’s related wave height and Z height etc. When customer to solder same PCB, they can get full information about how it’s done in history, also easy for trace.

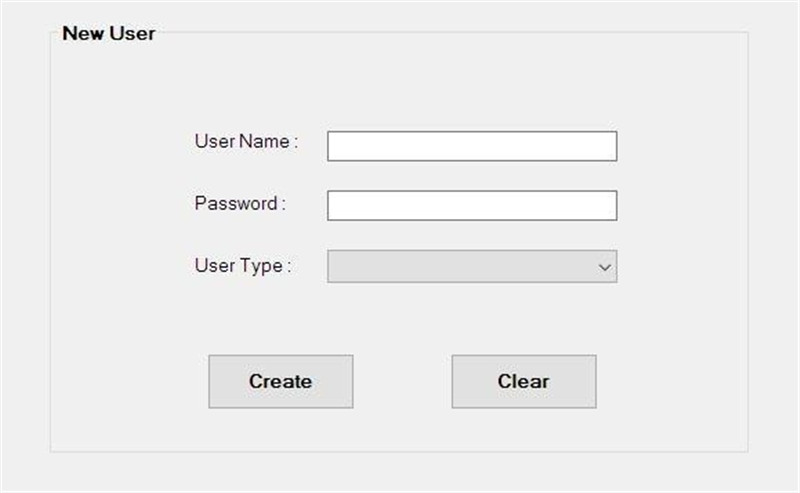

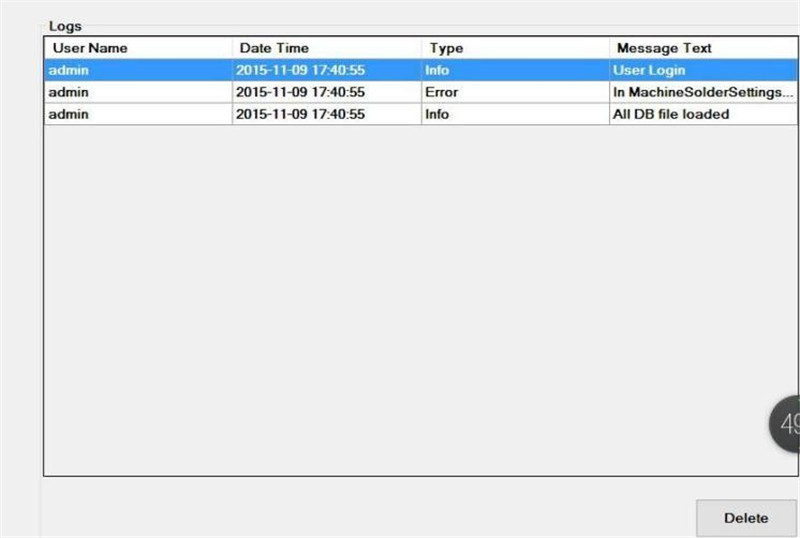

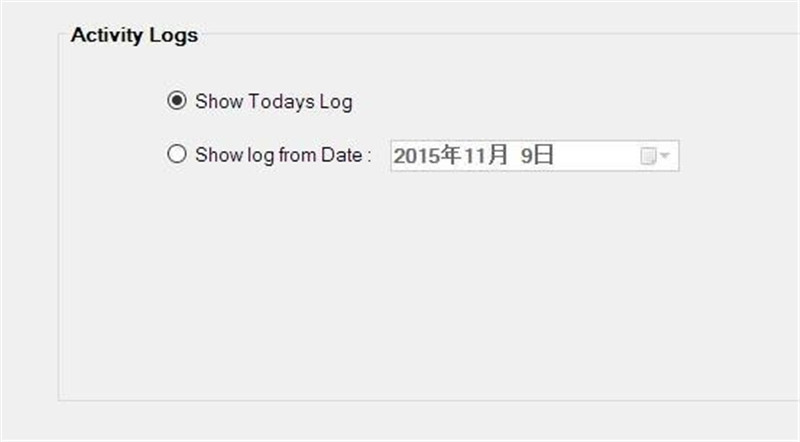

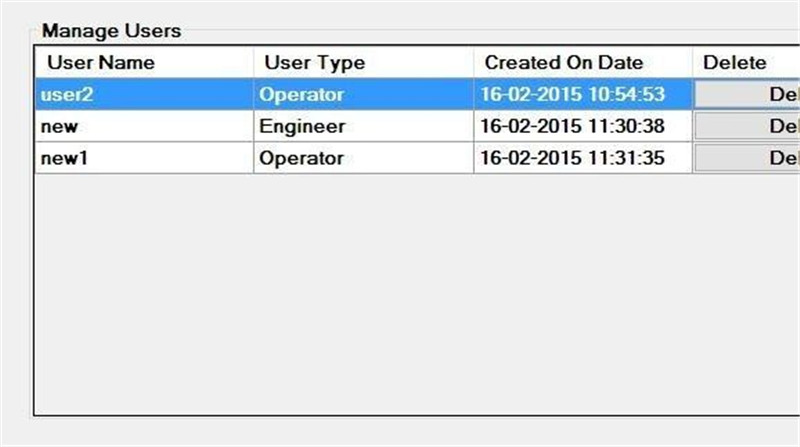

With LOG function, provide 3 level to enter software with different rights. Meanwhile, can record machine’s operation & alarm.

Part2: Motion System

Motion table was designed base on lighting concept.

Panasonic servo motor & driver provide stable driving power, screw pole & linear guild rail for guidance. Precious position, less noise, stable movement.

With dust proof plate above motion table, so to avoid flux or solder drop to damage ball screw.

Part 3: Fluxing System

Standard equipped with jet valve to get precious fluxing result with small flux dot. Flux is stocked by PP plastic pressure tank, make sure pressure stable without influenced of amount offlux.

Part 4: Preheat

Bottom preheating is standard equipped in machine, Position is adjustable.

Heating ratio is adjustable by PC, from 0 ---100%

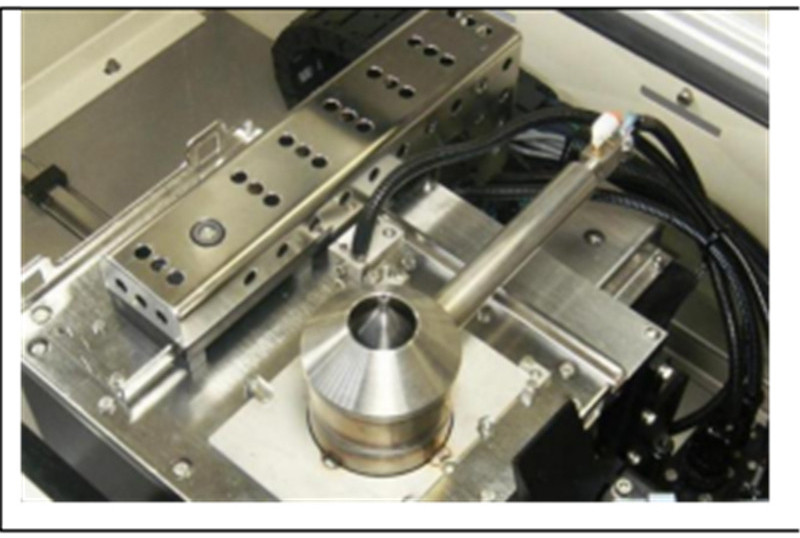

Part 5: Solder Pot

Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software.

Solder pot is made of Ti, not leakage. With cast iron heater outside, robust & quick heat up.

Solder pot is wired with quick connector. When exchange solder pot without re- wiring required, just plug & play.

N2 online heating system, to wet the soldering perfectly and reduce the solder dross. With solder level checking & alarm.